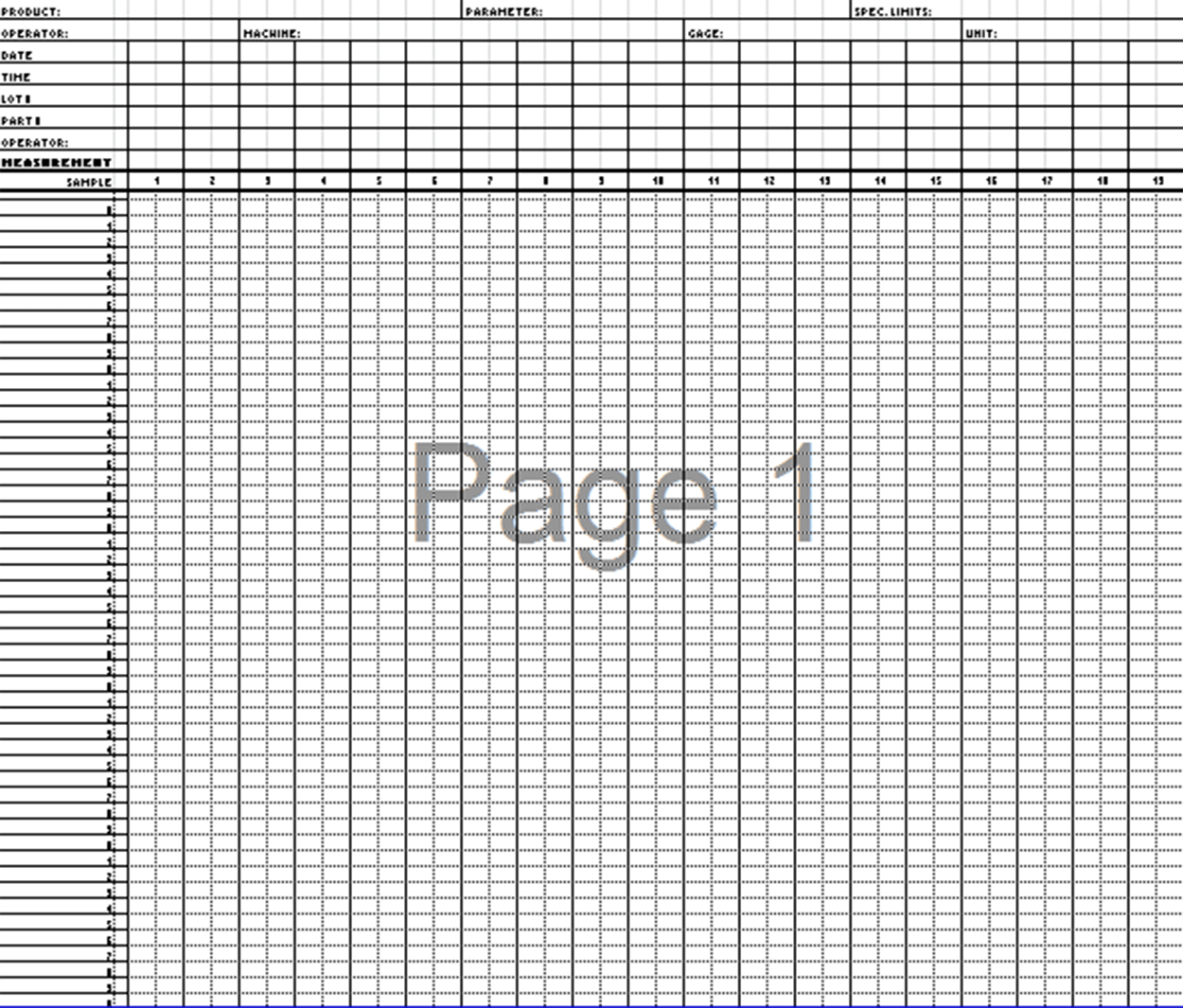

Online SPC certification course ( $350) or As revisions are released the menu's may change from that shown below however, the general path is likely. (Note: while making these recalculations, start with the R-chart first because calculation of limits for the X-bar chart requires the value for a good R-bar.). Select Observations for a subgroup are in one row of columns 4. The Xbar chart below shows an out of control process. An Xbar-R chart is a quality control chart used to plot subgroup means and ranges of individual values from a single characteristic on a given part that. In his online SPC Concepts short course (only $39), or his Go to Stat > Control Charts > Variables for Subgroups > Xbar & R: 3. Learn more about the SPC principles and toolsįor process improvement in Statistical Process Controlĭemystified (2011, McGraw-Hill) by Paul Keller, X-bar / Range charts are used when you can rationally collect measurements. Process capability is only meaningful when the process is stable, since we cannot predict the outcome of an unstable process.įixed or Varying Subgroup Sizes for X-Bar charts An X-bar & Range Chart with process capability estimates from SPC IV Excel software.

If the process shows control relative to the statistical limits and Run Tests for a sufficient period of time, then we can analyze process capability relative to requirements. (This can be done automatically using the Auto Drop feature in our SPC software). Remove the statistical bias of the out of control points by dropping them from the calculations of the average X-bar and X-bar control limits. Brainstorm and conduct Designed Experiments to find those process elements that contribute to sporadic changes in process location. If there are any out of control points on the X-bar Chart, then the special causes must be eliminated. Never consider the points on the X-bar chart relative to specifications, since the observations from the process vary much more than the subgroup averages. Once the effect of the out of control points have been removed from the Range chart, look at the X-bar Chart.Īfter reviewing the Range chart, interpret the points on the X-bar chart relative to the control limits and Run test rules. In this case, look at how you measure the variable, and try to measure it more precisely. If there are values repeated too often, then you have inadequate resolution of your measurements, which will adversely affect your control limit calculations. (This can be done automatically using the Auto Drop feature in our SPC software).Īlso on the range chart, there should be more than five distinct values plotted, and no one value should appear more than 25% of the time. Remove the statistical bias of the out of control points by dropping them from the calculations of the average Range, Range control limits, average X-bar and X-bar control limits. Brainstorm and conduct Designed Experiments to find those process elements that contribute to sporadic changes in variation. If there are any, then the special causes must be eliminated. On the Range chart, look for out of control points and Run test rule violations. The control limits on the X-bar chart are derived from the average range, so if the Range chart is out of control, then the control limits on the X-bar chart are meaningless.

#XBAR R CHARTS MANUAL#

Look for special or assignable causes and adjust the process as necessary to maintain a stable and in control process.įormulas from 2002, Manual on presentation of data and control chart analysis, ASTM International, West Conshohocken, PA.Always look at the Range chart first. With the control limits in place, gather samples, and plot the data. Once you decide to monitor a process and after you determine using an $- \bar$$ 8. Root Cause Analysis and the 8D Corrective Action Process course.An Introduction to Reliability Engineering.Reliability Analysis Methods online course.14 Ways to Acquire Reliability Engineering Knowledge and R chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously.Reliability Engineering Management DRAFT.Innovative Thinking in Reliability and Durability.Equipment Risk and Reliability in Downhole Applications.Musings on Reliability and Maintenance Topics.

Metals Engineering and Product Reliability.Product Development and Process Improvement.Rooted in Reliability: The Plant Performance Podcast.

0 kommentar(er)

0 kommentar(er)